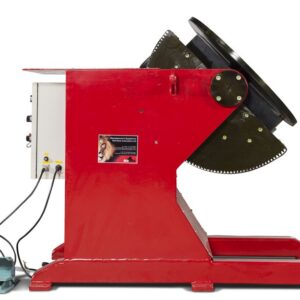

WELDING POSITIONERS FOR SALE

Redrock’s range of welding positioners, including 3 Axis Hydraulic Welding Postioners and Cradle Type Welding Positioners, provides you with the quickest and safest means of rotation and tilting through 360 degrees whilst retaining maximum access to the workspace.

Unlike a welding turntable, which rotates a workpiece around a vertical axis, a welding positioner offers horizontal rotation allowing for precise positioning and improved weld quality.

Improve your process with welding positioners from Redrock

Our range of welding positioners offers a way to equip your operators with high-quality, reliable and robust machinery to deliver results. Positioners can bear a significant weight safely, offering welders the ability to control rotation speed and tilt, as well as the option of manual or semi-automatic welding. Our welding positioners are the ideal solution for welders of any experience and skill, enhancing productivity and weld performance, and reducing time spent reworking.

Available worldwide through our network of global distributors, Redrock’s welding positioners help our clients increase their throughput to gain a competitive edge. Whether you’re looking for a variation in rotation speed or enhanced precision of welded workpieces, speak to Redrock about sourcing a positioner for your next welding job.

Why Redrock?

LOOKING FOR A WELDING Positioner?

LET US FIND THE BEST SOLUTION

WELDING POSITIONERS BY REDROCK

How does a welding positioner work?

Welding positioners enhance welding processes by using a rigid circular frame to securely hold a workpiece tightly, enabling a welder to work at various angles and on a stable surface. A positioner is capable of rotating at high speeds, even when supporting substantial weight.

Operators can then continue with the process without having to move around the workpiece, and so can take advantage of faster speeds and more control than a manual welding positioner.

Every welding process needs to be streamlined to maximise efficiencies, improve processes, minimise rework jobs and keep your operators welding. Material handling is an overhead you can reduce by lessening the time your operators spend handling materials.

Redrock welding positioners will help your organisation get the best quality output from every weld operator on your team, regardless of their skill level. With our positioners, your operators will be able to make more welds in the flat position, rather than spending longer to get the same quality of weld from out-of-position, which is an advanced skillset that not all your operators may have acquired.

Our range of welding positioners enable your operators to perform superior welds from a flat and horizontal position with speed, precision and far less reworking required.

All Redrock positioners are robustly designed to withstand the most demanding of environments. We have a range of sizes capable for small and large loads, and can be integrated with TIG, SAW, MIG/MAG welding processes, each suited to circumferential and longitudinal seam welding and with a 360 degree lockable rotation and gear tilt.

WELDING POSITIONERS DESIGNED WITH PRODUCTIVITY AND SAFETY IN MIND

Redrock have numerous models suited to different work environments. Every model across our range are robustly designed with 100% steel to withstand the most demanding of environments.

Our 3-Axis hydraulic positioners and chucks range have adjustable rotation speed settings and high angle rotation, letting your operators manipulate the weldment to suit the application. Heavy duty cradle positioners available for heavy loads and freestanding weld positioners capable of loads from 150KG to 100 tonnes.

All our positioners have low voltage (24v) remote pendent control and enhanced safety features.

Equip your welders with the best equipment for the job and watch your productivity sky rocket. Better yet, you’ll benefit from better deposition rates and lower dilution rates. Redrock welding positioners can be integrated into many processes including ESW strip cladding and SAW welding processes.

WHY REDROCK WELDING POSITIONERS ARE YOUR TOP CHOICE

All our positioners offer various features to truly improve your operations

- Robust all-steel fabrication

- Variable speed table rotation

- Round or square T-slotted tables with extension arms

- Table tilt

- Table elevation

- Enclosed electronic controls

- Remote push button pendant controls

All the features you need to…

- Save time and money

- Increase productivity

- Reduce operator fatigue

- All our welding positioners are fully guaranteed and warrantied for three years.

- Available worldwide

- Get access to a team of highly skilled professionals knowledgeable in the latest technologies in welding automation!

Whatever welding equipment you need, be it a welding positioner, manipulator, turntable or rotator – Redrock can service all your needs, anywhere in the world.

REQUEST MORE INFORMATION ABOUT OUR WELDING POSITIONERS

Leave your information below and a member of the Redrock team will be in touch to give you more information about Redrock’s welding positioners.

Explore our extensive range of welding positioner equipment

- WELDING ROTATORS

- WELDING MANIPULATORS

- WELDING TURNTABLES

WELDING ROTATORS

Redrock’s range of conventional and self-aligning welding rotators provides an economical and practical answer to cylindrical vessel rotating and handling problems.

WELDING MANIPULATORS

Redrock has a huge inventory of welding manipulators suited to any welding application, providing a safe and efficient efficient welding procedure suited to multiple industries .

We’re uniquely positioned to understand the pressures of the welding industry, and can provide the best quality welding manipulators to help our clients increase their through-put to gain a competitive edge.

WELDING TURNTABLES

Welding turntables are built to a heavy-duty precision design and are suitable for various applications, from fit-up and assembly requirements to integrated cladding and overlay applications.

Our fleet of welding turntables is suitable for a wide range of applications, from fit-up and assembly requirements to integrated cladding and overlay applications.