- For Hire

- For Sale

- Our Fleet

- Used Equipment

Redrock’s range of hire conventional and self-aligning welding turning rolls provides an economical and practical answer to oversized cylindrical vessel rotating and handling problems.

Tank turning rolls provide a mechanical way to rotate cylindrical vessels, working with larger diameter pipes. They minimise handling, increase efficiency and dramatically improve the quality of workmanship from welders of all skill levels.

Redrock can supply conventional and self-aligning turning rolls for hire on short or long terms to suit various sizes of weldments across a variety of sectors. Any steelworks with cylindrical vessels, be it small-diameter piping or large industrial cylindrical vessels for wind tower production will benefit from the use of a turning roll.

For any cylindrical welding processes, including SAW, TIG, MIG and MMA, turning rolls can make a huge difference to the quality of the weld.

Self-aligning turning rolls provide similar functionality to conventional turning rolls, however are built for smaller load capacities of up to 300 tonnes. Our self-aligning turning rolls have a drive unit with motorised wheels and an idling unit allowing for free-wheeling, making it easier to load vessels onto the rotator without damaging the drive unit.

Redrock’s self-aligning welding turning rolls feature two rollers that will adjust to accommodate the diameter of the vessel automatically. A range of specifications can be accommodated, including various vessel diameters and rotation speeds. Self-aligning turning rolls provide a faster load time with mechanical drive, where the wheel brackets and the wheels will automatically align any size of a cylindrical vessel.

The top rollers on self-aligning turning rolls have clutches allowing the rollers to freewheel, minimising the risk of damaging the drive unit from improper loading techniques.

Redrock’s conventional turning rolls are suited to industrial weld operations requiring a higher load capacity of up to 2,000 tonnes and suited to a wide range of fabrication shop setups.

While not self-aligning, the vessel diameters can be adjusted manually with speed. All our welding turning rolls use replaceable polyurethane tyres, mounted to cast steel drums giving the units tremendous durability and superior traction. As standard with all our welding equipment, a low-voltage remote-control pendant is included to give your operators full control over forward/reverse/stop/emergency stop and a potentiometer to vary the rotation speed and provide higher quality welds.

Frequently Asked Questions

There are many benefits of integrating turning rolls into your welding projects, including consistent weld quality across all cylindrical workpieces and weight capacities. With less manual material handling, your welders will experience less operator fatigue, contributing to enhanced safety in the workspace. A stable rotational speed paired with the reliable grip of any cylindrical vessel provides a way to increase productivity whilst maintaining a consistent high-quality circumferential weld.

Various models encompass different load capacities. Redrock offers equipment to support multiple load capacities, including 2,000t conventional turning rolls and up to 200t self-aligning turning rolls, with numerous features and customisations available.

Tank turning rolls are equipped to handle the rotation of larger and wider cylindrical objects, such as tanks and vessels, providing stability and precise rotation during welding or fabrication processes.

Pipe turning rolls are specifically designed for the rotation of long, narrow cylindrical pipes during welding or fabrication processes.

Selecting between pipe and tank turning rolls depends on the size and type of the cylindrical workpieces in your project. Pipe turning rolls are designed for long, narrower pipes and can handle smaller diameters with precise rotational control. Tank turning rolls, on the other hand, are suited for larger, heavier and wider vessels like tanks, offering greater stability for oversized diameters and weight capacities.

If you’re unsure, our team at Redrock Automation can guide you in choosing the right turning roll to suit your specific requirements.

Speak to our team to discover a bespoke solution for your welding automation requirements.

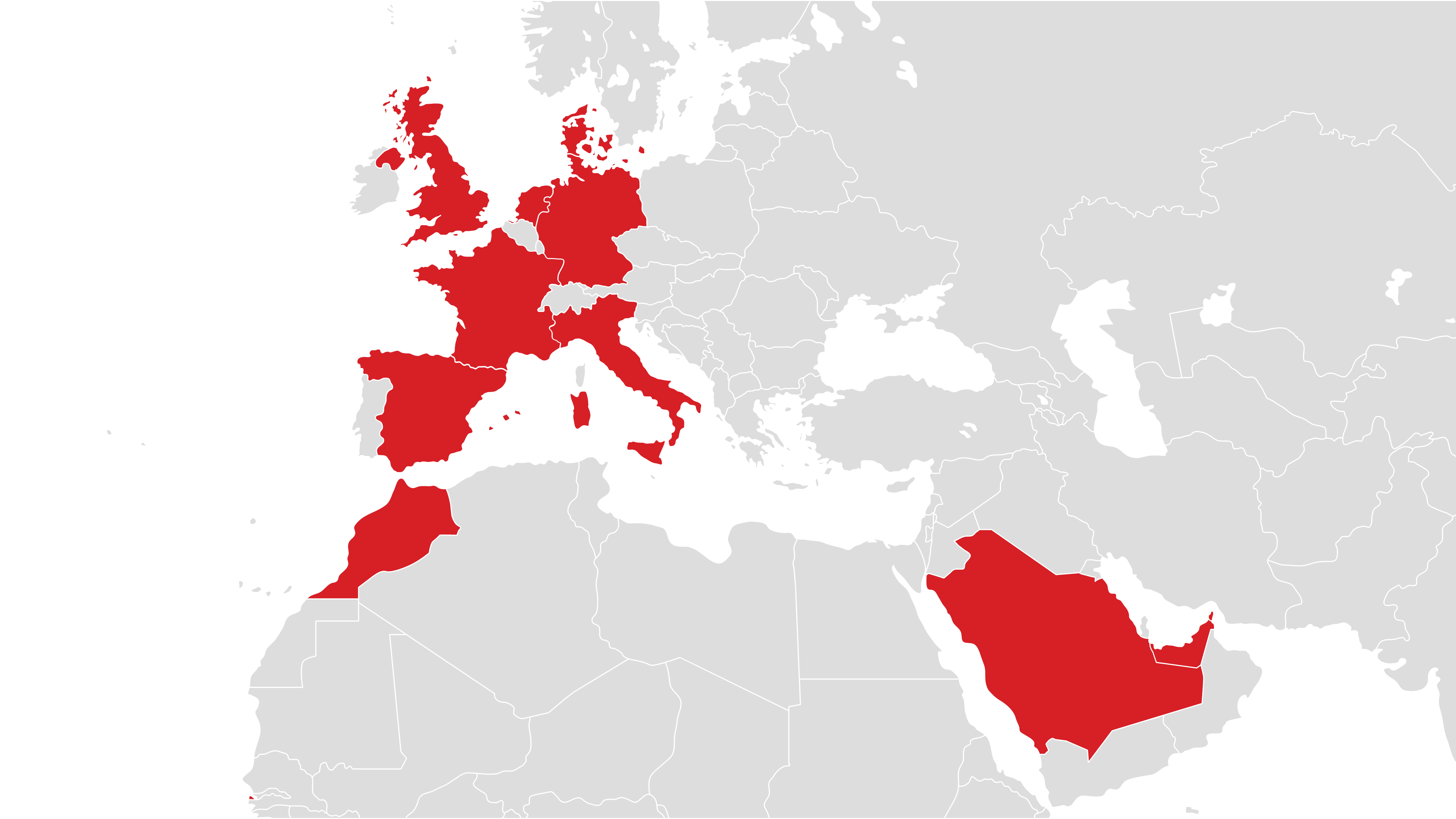

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.