- For Hire

- For Sale

- Our Fleet

- Used Equipment

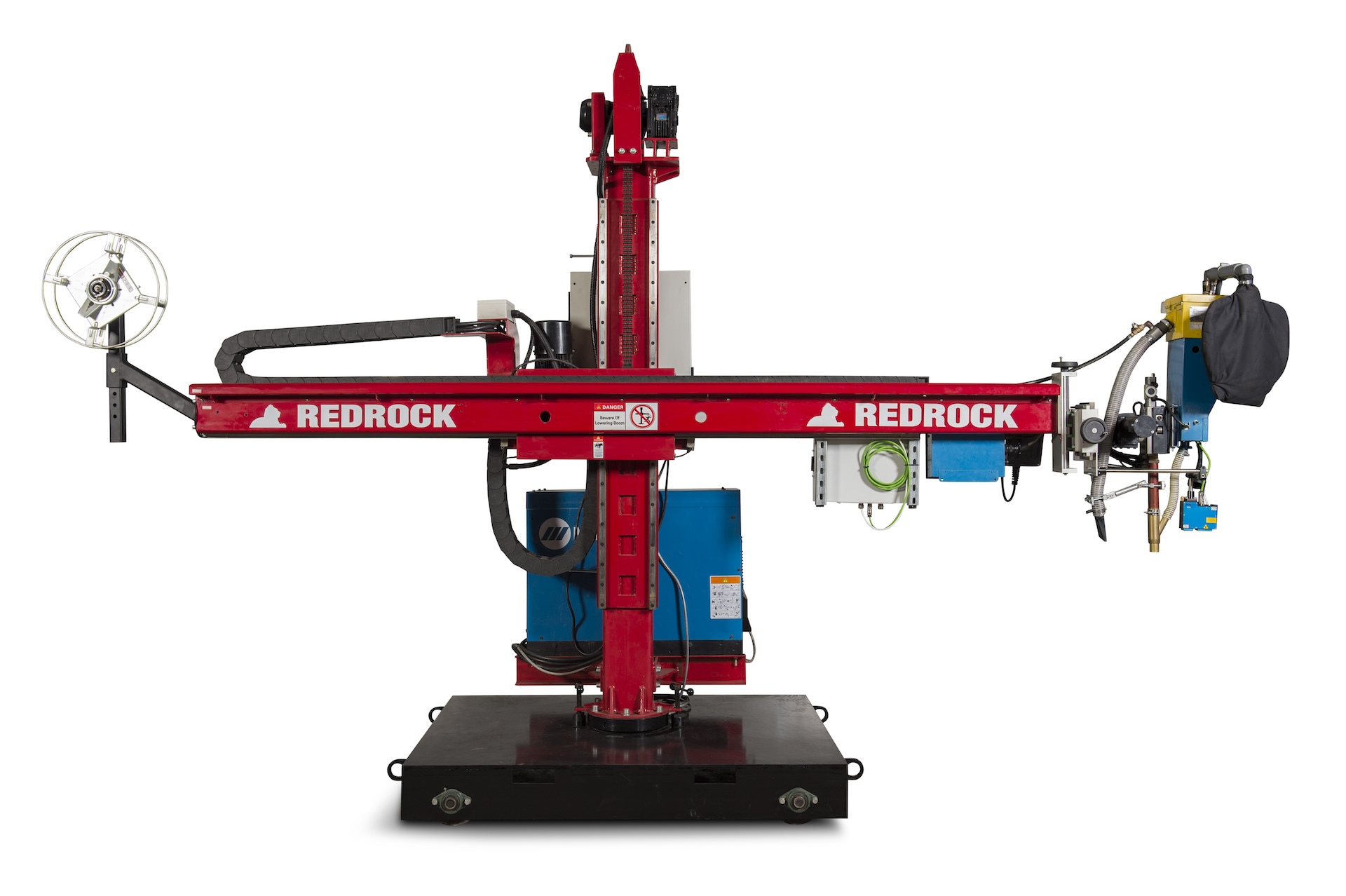

Redrock’s range of welding positioners provides the quickest means of rotating and tilting whilst retaining maximum access to the workspace, including Cradle Type Welding Positioners, 2 Axis and 3 Axis Hydraulic Welding Positioners.

Unlike a welding turntable, which rotates a workpiece around a horizontal access axis only, a welding positioner offers 0-135 degree tilt movement allowing for precise positioning and improved weld quality.

For Hire

Welding Positioners

Welding positioners

Our range of welding positioners offers a way to equip your operators with high-quality, reliable and robust machinery to deliver results, available for both short and long-term rental periods.

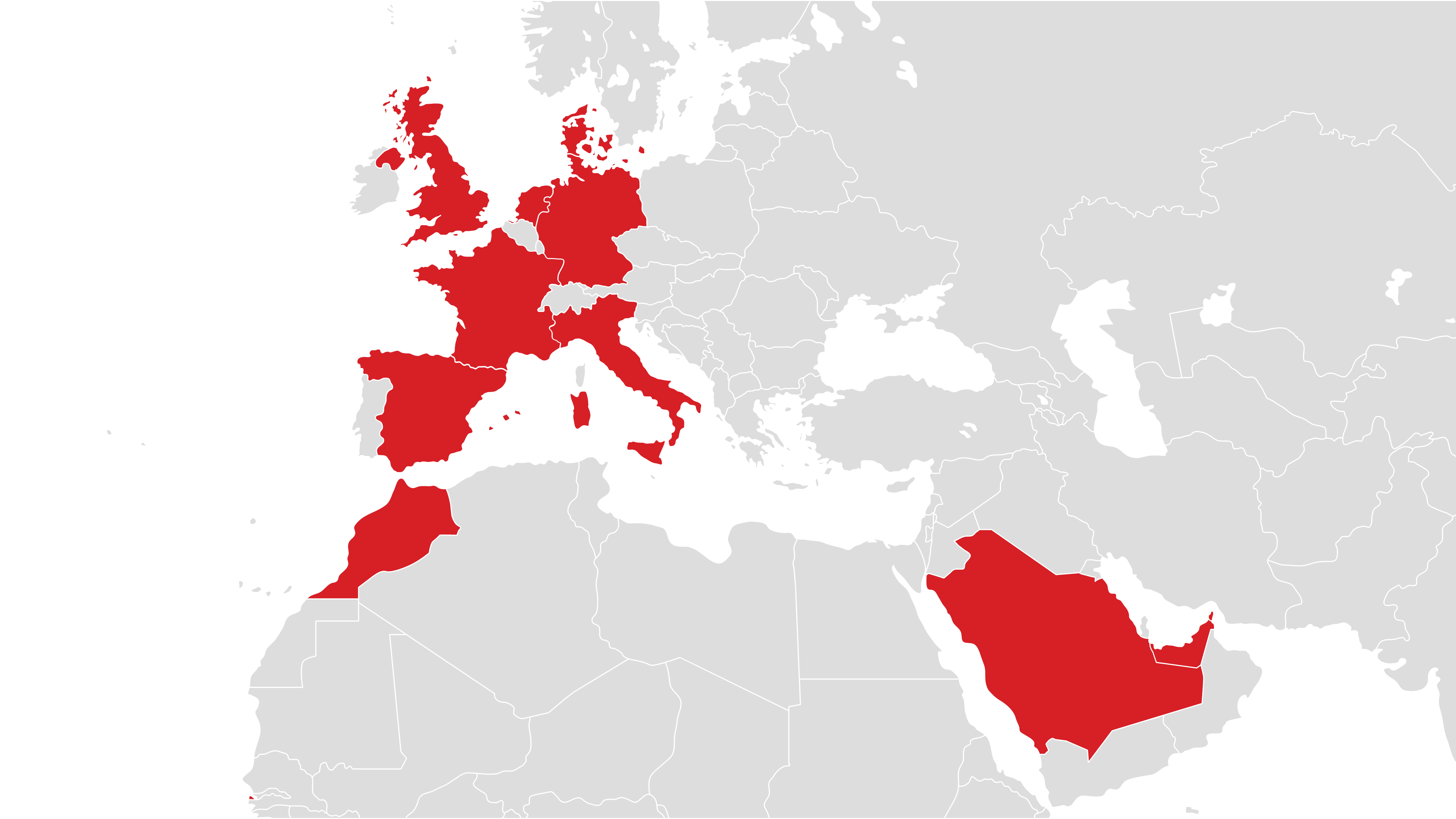

Available worldwide through our network of global distributors, Redrock’s welding positioners help our clients increase their throughput to gain a competitive edge.

Our welding positioners are the ideal solution for welders of any experience and skill set, enhancing productivity and weld performance, and reducing time spent reworking.

Frequently Asked Questions

The purpose of a welding positioner is to enhance welding processes by securely holding a workpiece in place and allowing it to be rotated to various angles. This ensures the welder can work on a stable surface, improving weld quality and consistency.

A welding positioner can rotate the workpiece at high speeds, even when supporting substantial weight. This capability enables operators to weld efficiently without needing to move around the workpiece, providing better control and faster operation compared to manual welding methods.

Welding positioners allow you to equip your workshop and welders with industry-leading equipment to get better welds and increased efficiency.

With a welding positioner, workers can spend more time focusing on achieving quality welds by using the equipment to move the workpiece into place in a non-contact work piece position, rather than attempting to weld whilst standing in sub-optimal positions.

Less experienced welders on your team will be equipped with the skill set to produce superior quality welds typically expected from advanced welders, meaning your output will be of a consistent quality. With our positioners, your operators will be able to achieve more welds in the downhand position, rather than welding positionally, which is an advanced skill set that not all operators may have acquired.

Hiring a welding positioner from Redrock will ultimately help you to improve your cash flow.

Not all jobs call for a welding positioner – they’re often used on bigger jobs, then set aside for a period of time. By hiring a positioner, you’ll only pay for it when it’s needed, and it can be returned to us when done.

For more details on the benefits of renting versus purchasing, see our blog post on Why Rent Welding Equipment.

All our positioners offer various features and components to improve your operations, increase control and manufacture results for your processes:

Redrock’s range of conventional and self-aligning welding rotators provides an economical and practical answer to cylindrical vessel rotating and handling problems.

Our welding turntables are built to a heavy-duty precision design and are suitable for various applications, from fit-up and assembly requirements to integrated cladding and overlay applications.

Redrock has a huge inventory of welding manipulators suited to any welding application, providing a safe and efficient welding procedure suited to multiple industries.

Speak to our team to discover a bespoke solution for your welding automation requirements.

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.