- For Hire

- For Sale

- Our Fleet

- Used Equipment

Invest in efficiency with Redrock’s range of welding turntables, designed to enhance accuracy, productivity and safety. Suitable for a wide range of applications, a welding turntable can provide the highest levels of precision for your project.

Our welding turntables are built to a heavy-duty precision standard, engineered to handle various load capacities and elevate the welding process when working with large welding pipes and cylindrical vessels.

Welding turntables are suitable for multiple use cases, from fit-up and assembly requirements to integrated cladding and overlay applications. With durable construction and advanced engineering, Redrock’s welding turntables are a long-term investment that ensures precision and reliability for every project.

Welding turntables allow welders full control to adjust the rotation speed, angle and positioning, providing a uniform, high-quality weld across any diameter or workpiece. This level of precision helps reduce defects and waste and promotes structural integrity across various load capacities and use cases.

Our heavy-duty welding turntables provide a long-term solution for businesses looking to streamline operations with the right equipment, increasing throughput and maintaining high welding standards across all applications. Our range of welding machinery for sale equips your business with a stable investment in your welding processes.

Without a turntable, welders must position themselves around the workpiece whilst maintaining a consistent arc length to ensure an air-tight weld – a process that even some of the most skilled welders can struggle with. Welding turntables automate this process, as well as tilting vessels, piping or industrial components, for the best results. With full control over rotation speed, angle and position, the operator can prioritise weld quality and prevent strain.

Our welding turntables are designed to enhance precision, efficiency, and safety across a diverse range of industries, addressing unique challenges and elevating operational performance. Whether you’re in shipbuilding, pipe welding, or another specialised sector, our turntables adapt to your needs with unmatched reliability.

Frequently Asked Questions

Welding turntables are essential for any fabrication environment to increase output and productivity. They offer assistance with the welding of any pipe or rounded objects, providing welders with unparalleled consistency throughout the welding process, no matter the sizes or load capacities.

Welding turntables offer your workforce an increased level of productivity and speed due to the enhanced ergonomics that operators can take advantage of, meaning no need to weld in awkward positions. An improved work environment can then lead to less absenteeism and sick days, meaning fewer setbacks on projects and no need to hire temporary or less experienced welders to bolster your team.

These welding machines offer an easy-clean surface for your workers, meaning more time can be spent producing a superior weld throughout your job and less time cleaning equipment. With a turntable supplied by Redrock, you can take advantage of complete control of speed, angle and rotation throughout your project.

Various models encompass different load capacities. Redrock offers turntables to support multiple load capacities, from 5-tonne horizontal welding turntables to 100-tonne turntables.

We stock an extensive range of turntables to handle load capacities from 5-tonne to 100-tonne. Redrock’s turntables incorporate precision design elements to enhance the quality of your team’s work.

Suitable for multiple use cases, turntables offer various rotation speeds and tilting angles to help achieve optimal results. Paired with double gearboxes and heavy-duty slip rings, welding turntables provide an ideal solution for any important project.

Our fleet is available with a low-voltage remote control device with multiple customisation options, ensuring that any welding turntable is suited to your exact requirements. All our fleet is warrantied for three years and fully tested before being supplied to you, so you can ensure your equipment is ready for extensive use with any workpiece.

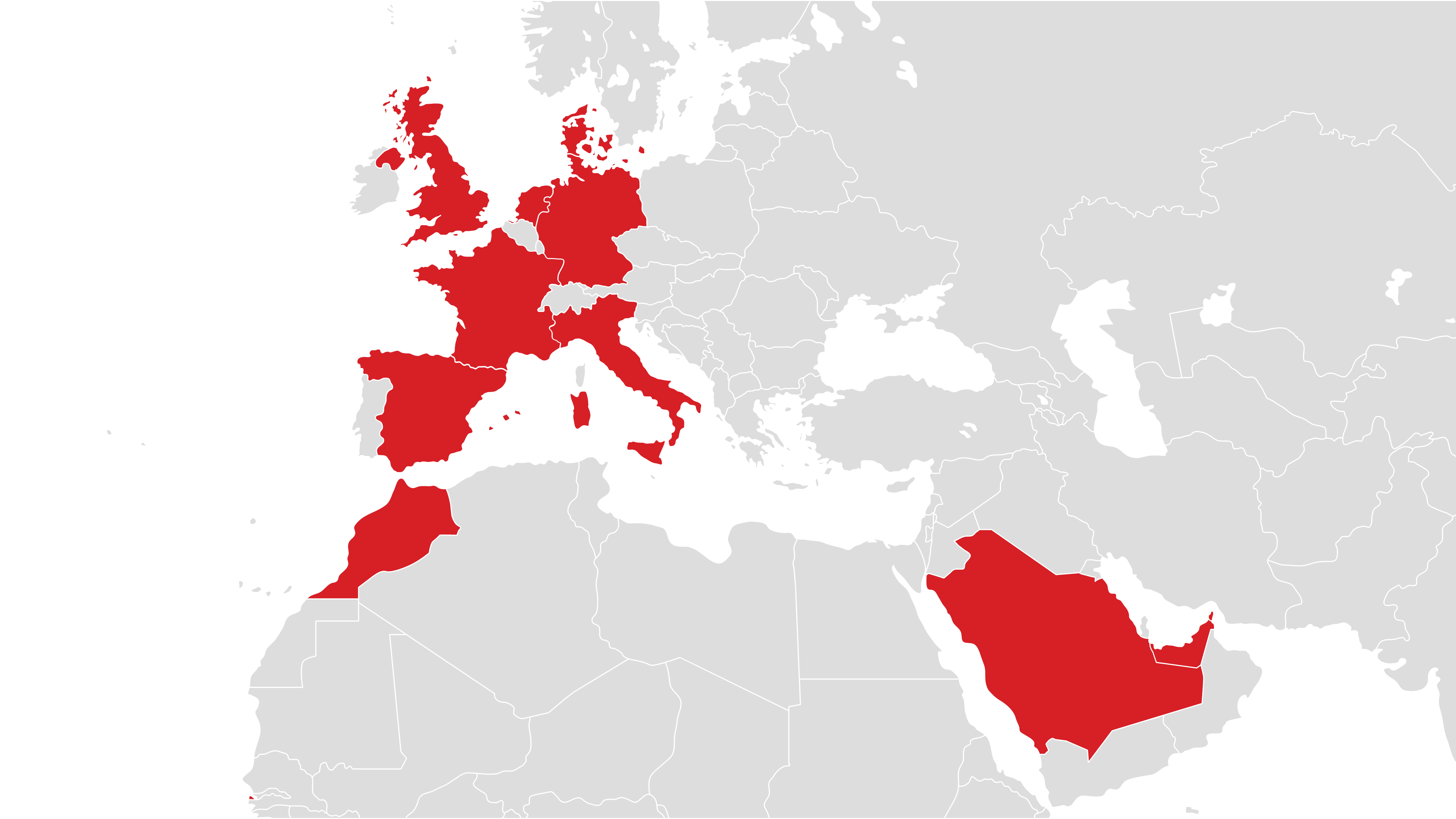

Our global team is equipped with the required skill set and industry experience to supply you with the equipment you need to complete any welding project and streamline your purchase with worldwide availability from our various facilities around the world. Whether you’re looking for turntables, welding positioners or something more bespoke, we’re here to help you find the right type of machinery for your requirements.

Whilst both welding machines are essential tools used to facilitate the rotation and positioning of workpieces, the main difference is in the axis of rotation.

Welding positioners rotate a workpiece through 360 degrees and tilt, whilst turntables rotate workpieces on a horizontal axis.

Speak to our team to discover a bespoke solution for your welding automation requirements.

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.