- For Hire

- For Sale

- Our Fleet

- Used Equipment

To ensure your welding equipment is built to last and provide results, the correct calibration of this is crucial.

Equipment calibration is key to measuring the performance and effectiveness of machinery, whilst assisting in highlighting any inadequacies that may benefit from refurbishment.

In short – yes. Certified welders in the industry who utilise welding equipment must routinely calibrate it to ensure they continue to meet industry quality assurance standards.

Ensuring your equipment remains in good condition with servicing is crucial to extending the life of any machinery, however without consistent calibration, equipment can become dangerous and potentially cause harm to your team.

No matter your equipment or industry, the benefits of calibration are numerous. From long-term cost savings to increased welder safety, properly calibrated equipment is an investment in your team and the future of your business.

Many operational factors can go wrong if you choose not to maintain or calibrate your equipment correctly. The reliability of your machinery will decrease, resulting in an unsafe work environment for your employees, as well as an overall decreased level of welding quality.

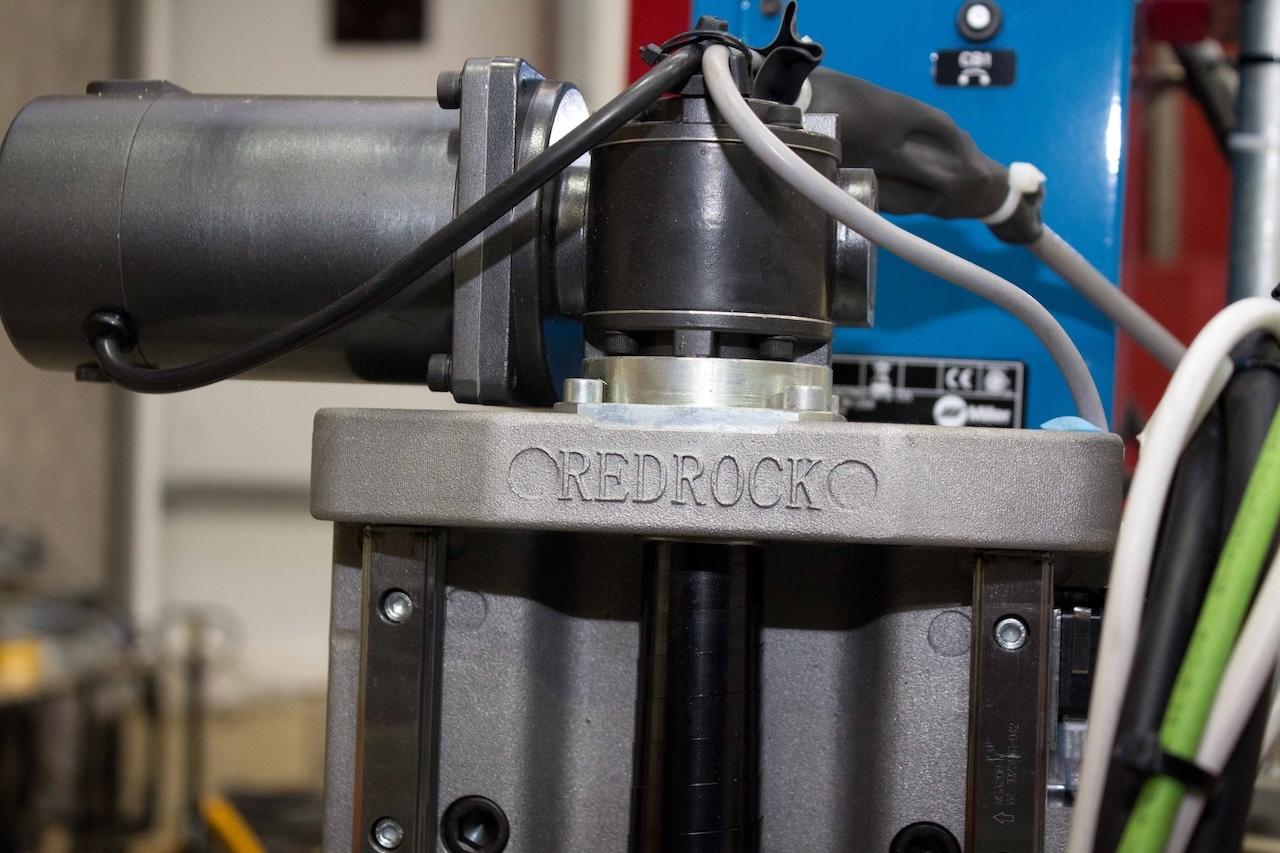

Explore Redrock’s range of welding equipment services that will provide you with a one-stop shop for all your welding automation needs.