- For Hire

- For Sale

- Our Fleet

- Used Equipment

Redrock Automation offers several types of portable welding fume extractors for hire that are developed to support the safe and efficient removal of welding-related fumes from your work site.

Welding fume extraction equipment is specifically designed to capture and remove harmful fumes and matter that are generated throughout the welding process. Such fumes can contain multiple toxic substances which can pose serious health risks to your workforce if not properly managed.

Fume extractors

Choosing the correct welding fume extractor for your workplace is a crucial decision to ensure the safety of your workforce.

Health Protection: Thanks to the efficient capture and removal of hazardous fumes and particulate matter, your welders will benefit from reduced exposure to toxic substances, as well as an enhancement to overall air quality in your worksite.

Regulatory Compliance: Safety is the ultimate goal of any workplace – investing in fume extractors for your business allows you to comply with any occupational health and safety regulations, whilst minimising the risk of health-related claims and legal issues that may stem from poor air quality.

Productivity: With a safer working environment, worker productivity is set to increase, leading to the continuation of smooth welding procedures and enhanced throughput for your business.

Redrock’s range of conventional and self-aligning welding rotators provides an economical and practical answer to cylindrical vessel rotating and handling problems.

Redrock is uniquely positioned to understand the pressures of the welding industry. We provide the best-quality welding positioners to help our clients increase their throughput to gain a competitive edge.

Our welding turntables are built to a heavy-duty precision design and are suitable for various applications, from fit-up and assembly requirements to integrated cladding and overlay applications.

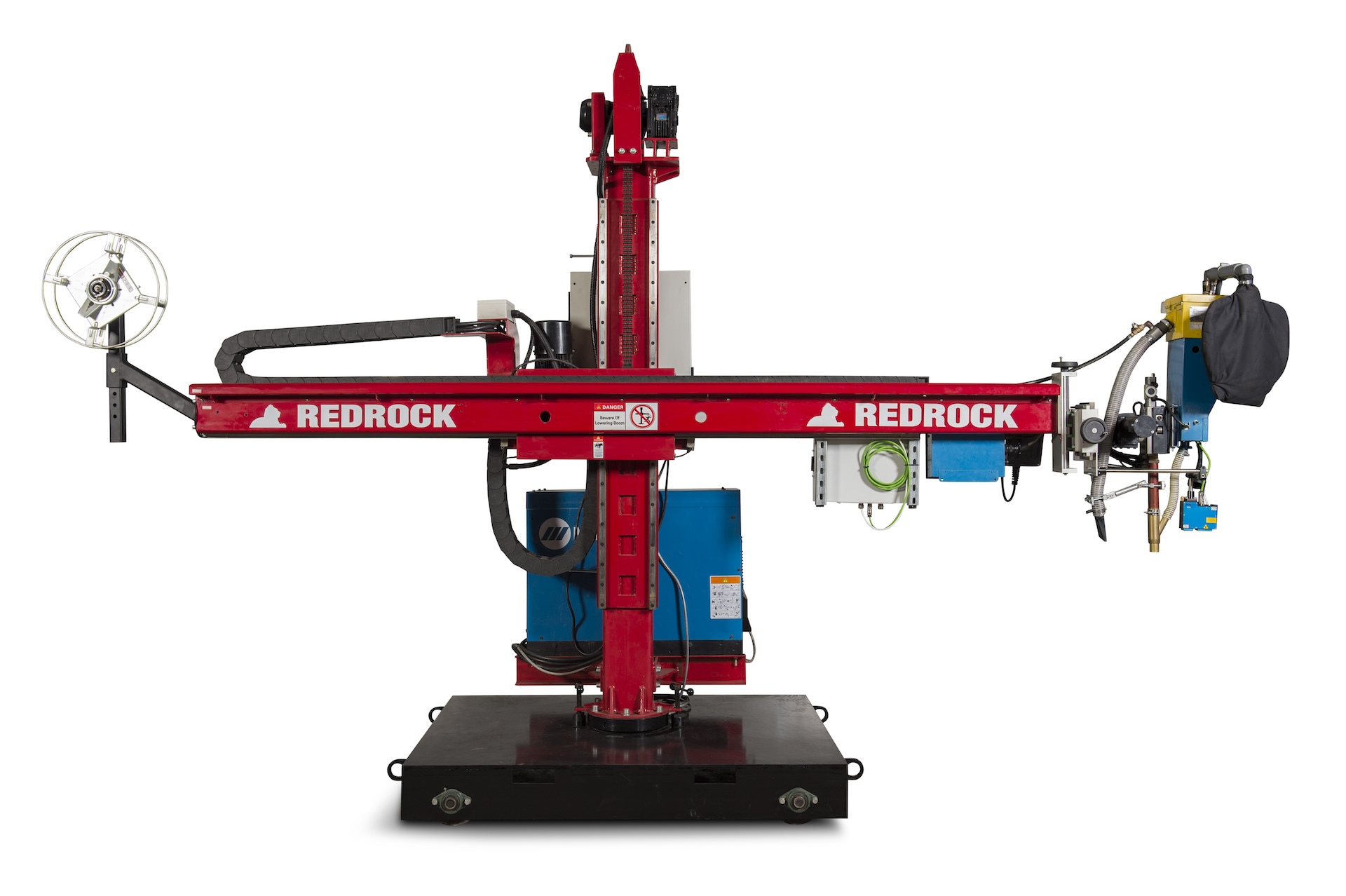

Redrock has a huge inventory of welding manipulators suited to any welding application, providing a safe and efficient welding procedure suited to multiple industries.

Speak to our team to discover a bespoke solution for your welding automation requirements.

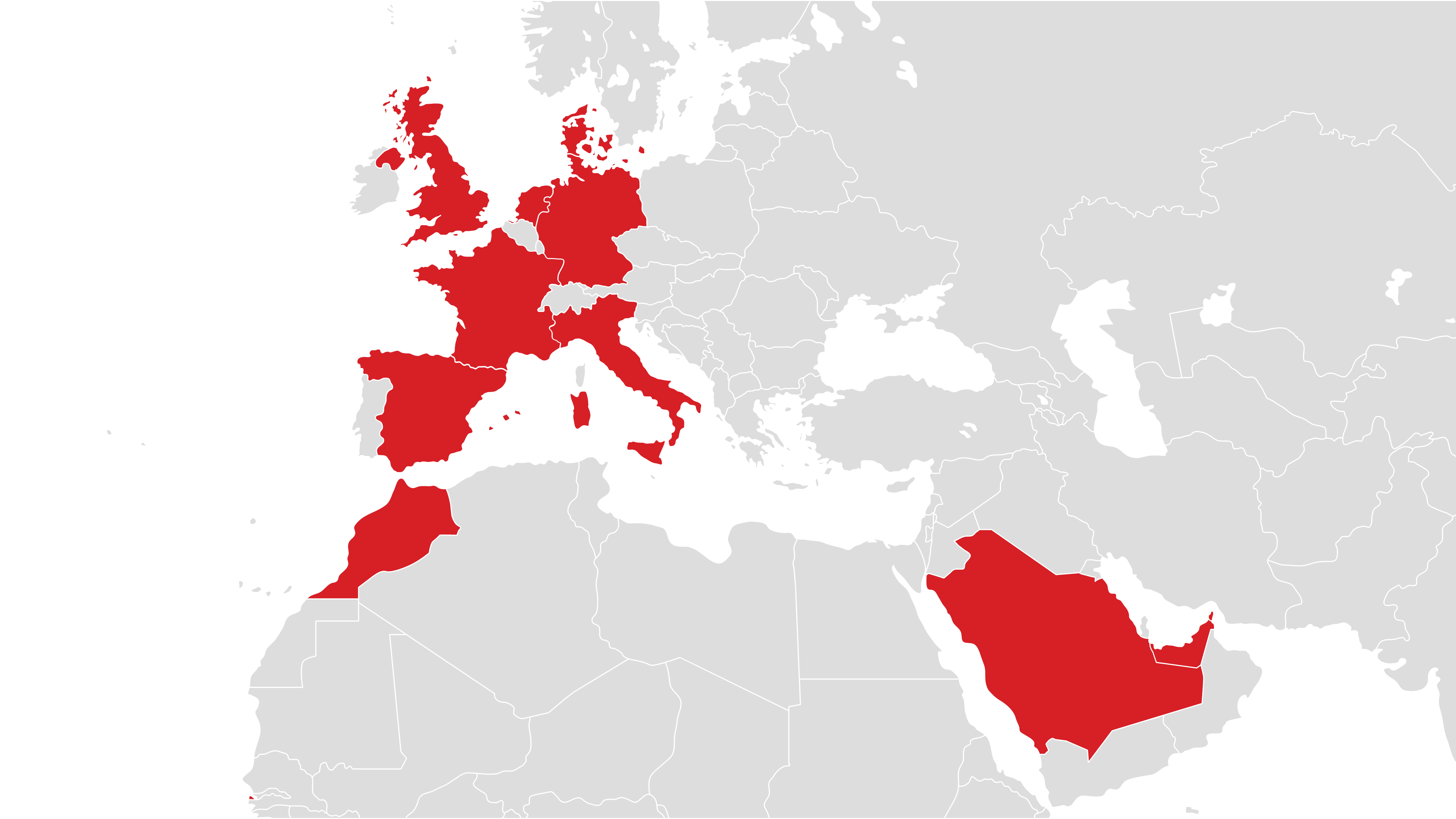

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.