- For Hire

- For Sale

- Our Fleet

- Used Equipment

Flux recovery systems can reduce operational costs by up to 50% and still maintain a continuous high-capacity weld with zero compromise on quality.

Benefit from better-quality control with the ability to eliminate fine particle flux too. And with a heated hopper, there are no concerns of the flux getting wet as the high temperature (150°C and adjustable) in the flux hopper, recovered flux stays dry.

The Redrock RR40 flux recovery system offers a solution for extremely cost-efficient weld automation with a continuous and uninterrupted high capacity to increase productivity.

Improve your quality control processes and reduce rework with flux recovery equipment that’s an essential part of the sub arc welding process, allowing for high deposition rates and no compromise on quality.

Benefit from enhanced health and safety and enhanced working conditions thanks to a reduction in fumes and risk splatter, with the entire weld process being contained under the flux.

Afterwards, flux is fully recovered, recycled and ready for reuse – all completely automated.

Redrock’s range of conventional and self-aligning welding rotators provides an economical and practical answer to cylindrical vessel rotating and handling problems.

Redrock is uniquely positioned to understand the pressures of the welding industry. We provide the best-quality welding positioners to help our clients increase their throughput to gain a competitive edge.

Our welding turntables are built to a heavy-duty precision design and are suitable for various applications, from fit-up and assembly requirements to integrated cladding and overlay applications.

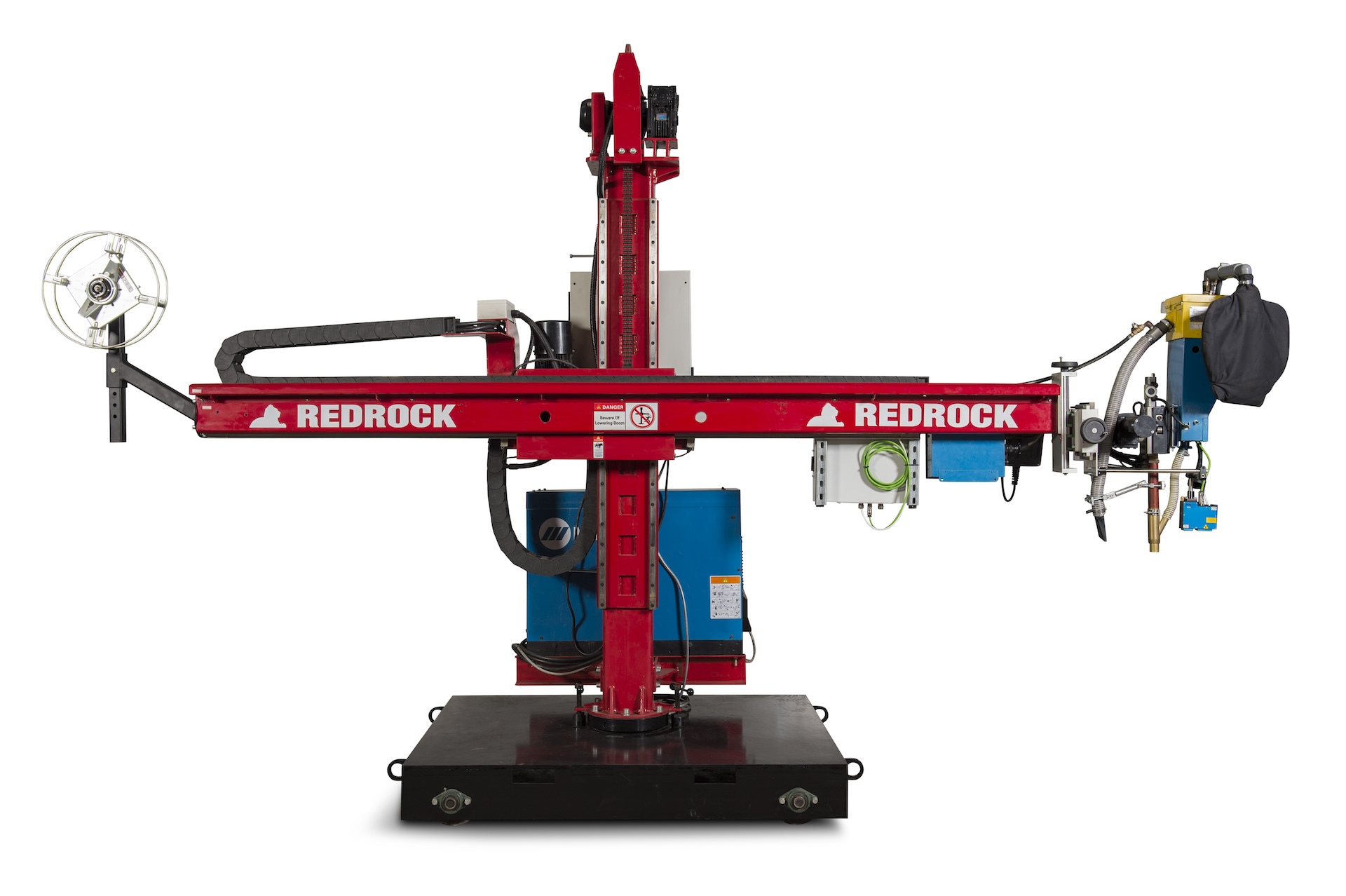

Redrock has a huge inventory of welding manipulators suited to any welding application, providing a safe and efficient welding procedure suited to multiple industries.

Speak to our team to discover a bespoke solution for your welding automation requirements.

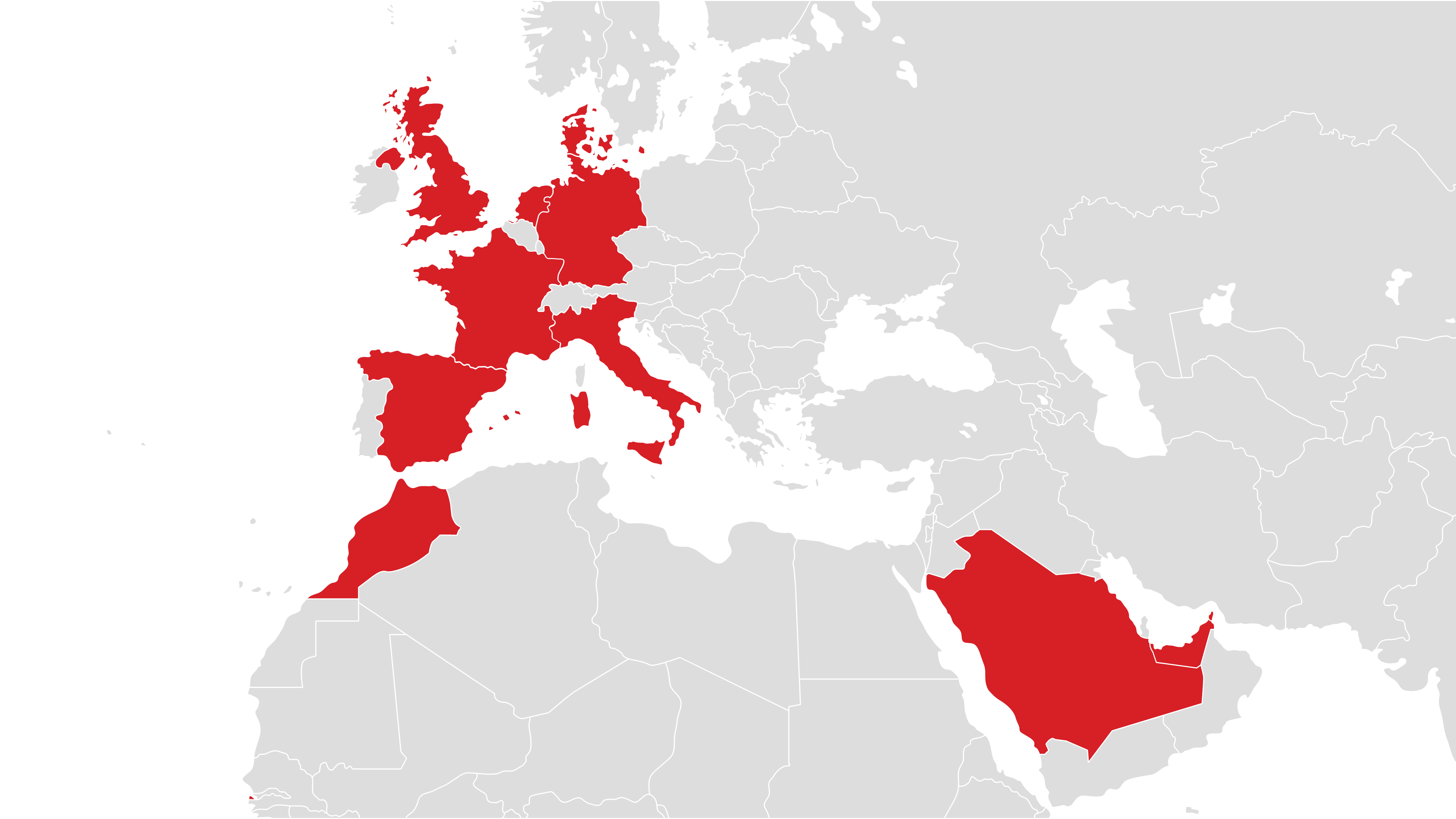

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.