- For Hire

- For Sale

- Our Fleet

- Used Equipment

Redrock’s sub arc welding (SAW) packages are suitable for a range of fabrication shops and industrial applications. With the right setup, your welding operations can be optimised to deliver top-quality welds faster, with better efficiency and higher deposition rates.

Redrock’s range of submerged arc welding packages is suitable for various large-scale infrastructure projects, including wind turbines, bridge-building components, rail carriages and oil rigs.

SAW is widely used in fabrication industries for welding large structural parts and is particularly applicable to working with very thick sections of steel, facilitating high throughput and producing higher quality welds with excellent mechanical properties.

Submerged arc welding is commonly used in shipbuilding industries for welding large steel structures due to its effectiveness in deep weld penetration of thicker steel with higher temperatures.

Welding processes in the automotive industry are often supported by submerged arc welding, offering both significantly deep penetration and high deposition rates.

The submerged arc welding process is often utilised in railway construction, offering increased productivity, streamlined operations and facilitating high throughput with high-quality welds.

Submerged arc welding gets its name from the process itself.

The welding process is invisible to the eye as it happens under a thick layer of flux – the flux is conductive when molten, allowing the current to pass to the workpiece without any sparks, splashing or fumes. The flux is fed from a hopper through a weld head using a continuous feed. Depending on the setup, one to five wires (electrodes) are continuously fed to maintain an arc under the flux. Excess flux can be collected via a flux recovery system for reuse.

The main components needed for a submerged arc weld system are:

Redrock can supply a variety of auxiliary equipment for sale or hire to support the submerged arc process.

Sub arc tractors are ideally suited for portability in workshops requiring the SAW process for a range of applications. As the tractor is portable, you can move it to the workpiece, reducing manual handling of objects. These are suited to long and straight weld operations on workpieces up to 10 feet. A sub arc tractor provides operator comfort and ease of use via a digital control panel, and in some systems, one central unit will control the weld parameters, such as speed and polarity, as well as the SAW tractor unit, instead of two control panels.

For welding large objects, the weld head on the SAW system can be positioned above the workpiece and combined with a rotator to turn the object at a consistent speed.

We can supply conventional and self-aligning welding rotators – speak to our team for advice and pricing.

Positioners can be used to increase operator efficiencies in manual weld operations or integrated into a mechanical process.

We stock a variety of positioners suitable for a range of operations, such as our 3 axis hydraulic positioners with adjustable speed and high angle rotation allowing welders easier manipulation. We also stock heavy-duty cradle positioners for loads from 150KG to 100 tonnes.

For automating the welding process of large cylindrical objects such as wind towers and pressure vessels, positioners can be integrated to optimise the work process.

Sub arc weld manipulator systems have multiple components including a flux recovery system and motorised travel car with forward and reverse motions at various speeds. These can be integrated with column and boom manipulators and other models, with remote camera systems available. Cameras can increase the quality of weld further as the weld head, alignment and process are visible, with some camera models able to provide additional lighting for increased visibility.

Frequently asked questions

Wire electrode and wire feeder: A wire electrode is continuously fed into the weld pool, with a wire feeder being used to control the wire feed speed.

Power source and control unit: A power source is used to generate the electric arc, paired with a control unit that sets and controls the welding parameters.

Mechanised travel and flux hopper: Mechanised travel is used to move the welding system or workpiece. A flux hopper is used to store and feed the granular flux.

The initial setup costs of SAW can vary depending on multiple factors, including the welding operation itself, specific application requirements, materials, power sources and welding parameters.

However, the SAW process is generally considered to be a cost-effective welding process that’s well worth the investment.

The submerged arc weld cladding process involves welding a layer of a different material to the surface of a cheaper material.

This reduces the cost of the material or allows the use of an alloy not suitable in its virgin form.

SAW cladding is a useful process for enhancing the surface properties of thin materials by adding a hard wear-resistant layer on top.

It’s widely used across multiple industries to improve the performance and longevity of critical equipment, including pipelines in the oil and gas industry, and turbine blades and boiler tubes in power generation use cases.

As flux is continuously fed from a hopper in a sub arc system, a flux recovery system is pivotal to reducing operational costs. The most efficient flux recovery systems can automatically separate molten slag and dust from used flux, returning only the usable flux to the hopper for reuse.

With automatic slag removal and separation of contaminated flux, labour time is reduced. As all flux returned to the hopper is free from contaminants, the quality of weld remains consistently high. Naturally, recycling flux provides operational savings.

The submerged arc process is closely related to arc welding, however it differs in several details.

The SAW weld zone is submerged under a flux covering and so offers workers higher levels of protection, whereas the arc welding process can also be shielded by gas, depending on the method in use.

SAW benefits from a high deposition rate that makes the submerged arc welding process ideally suited for thick plates and deep welds. Other arc welding processes can vary, with the likes of GMAW and SMAW offering moderate rates and GTAW being slower but highly precise in weld quality.

SAW processes are highly automated and offer control over various parameters including travel speed and weld position, whilst arc welding can range from manual processes through to semi-automatic.

The flux covering featured in SAW processes achieves a generally clean weld due to minimal splatter – other welding processes can vary, with SMAW generally producing more spatter and GMAW/TIG offering cleaner welds.

The SAW process is highly versatile and can be used to provide a clean weld for many materials. It’s commonly utilised with high and low-alloying elements, including medium-carbon and stainless steel, as well as nickel-based alloys and other metals.

Speak to our team to discover a bespoke solution for your welding automation requirements.

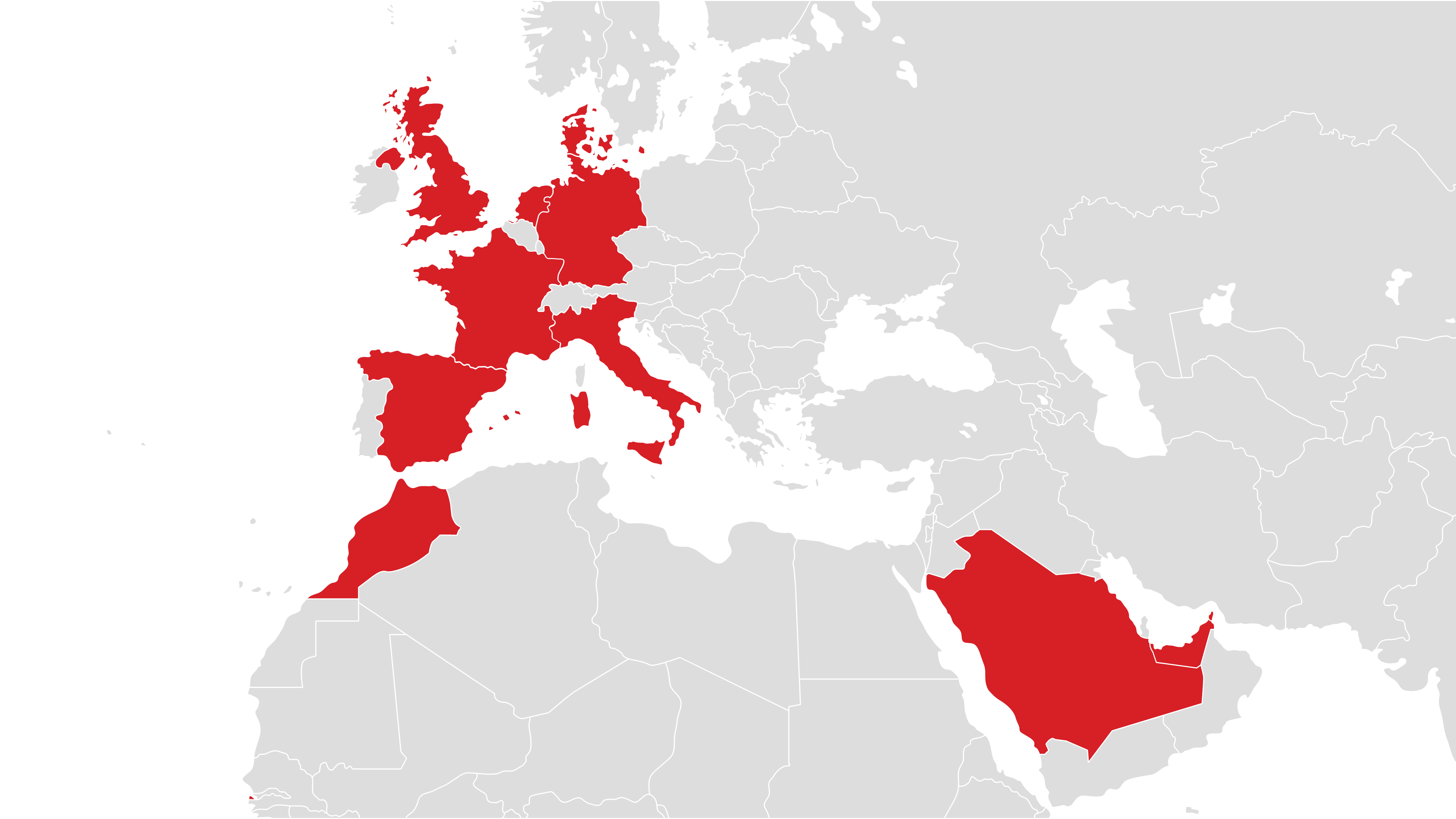

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.