- For Hire

- For Sale

- Our Fleet

- Used Equipment

Ideal for the manufacturing of large structures, a fit up bed and growing line system offer manipulation of large components during the assembly process.

A fit up bed and growing line system provides an innovative solution for manufacturing large structures in offshore and wind tower production.

A fit-up bed and growing line system offers several advantages in the fabrication process:

Redrock’s range of conventional and self-aligning welding rotators provides an economical and practical answer to cylindrical vessel rotating and handling problems.

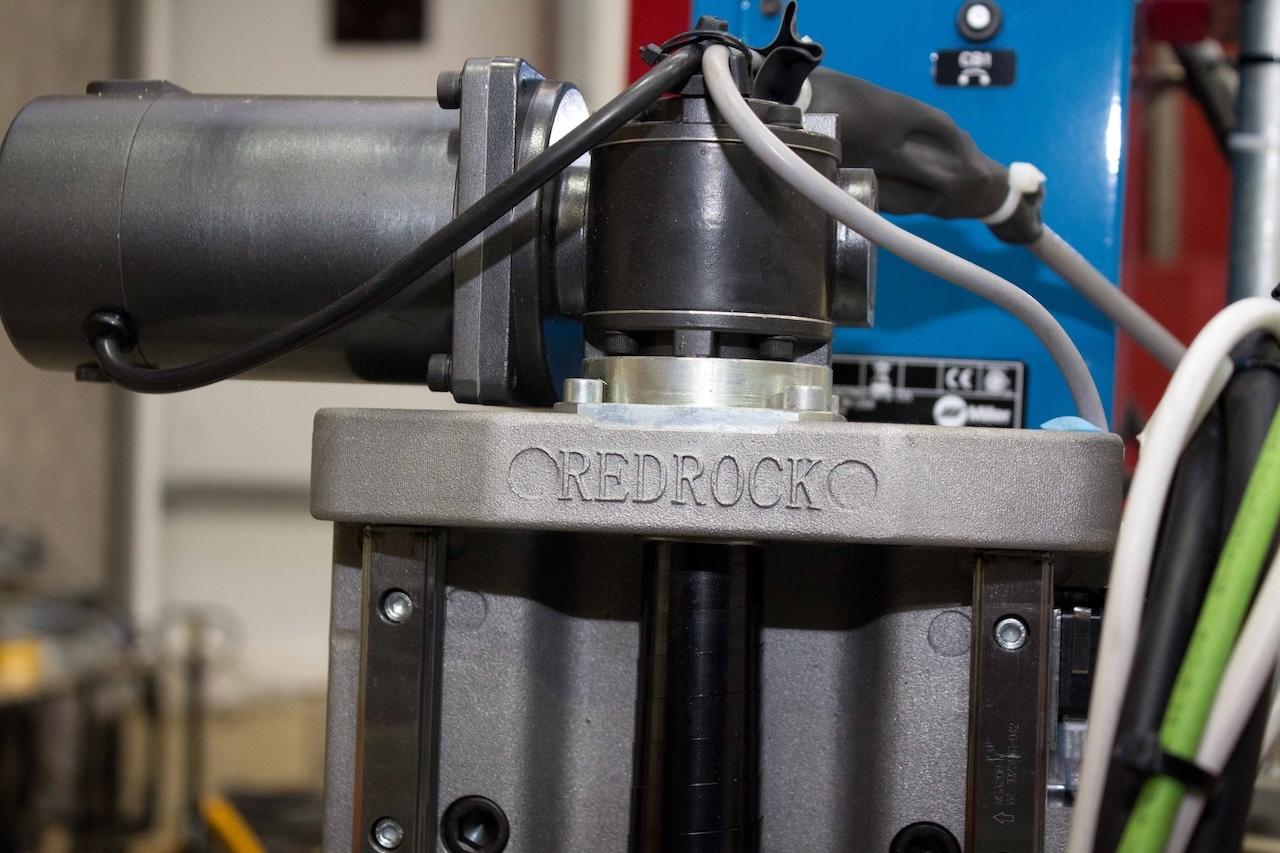

Redrock is uniquely positioned to understand the pressures of the welding industry. We provide the best-quality welding positioners to help our clients increase their throughput to gain a competitive edge.

Our welding turntables are built to a heavy-duty precision design and are suitable for various applications, from fit-up and assembly requirements to integrated cladding and overlay applications.

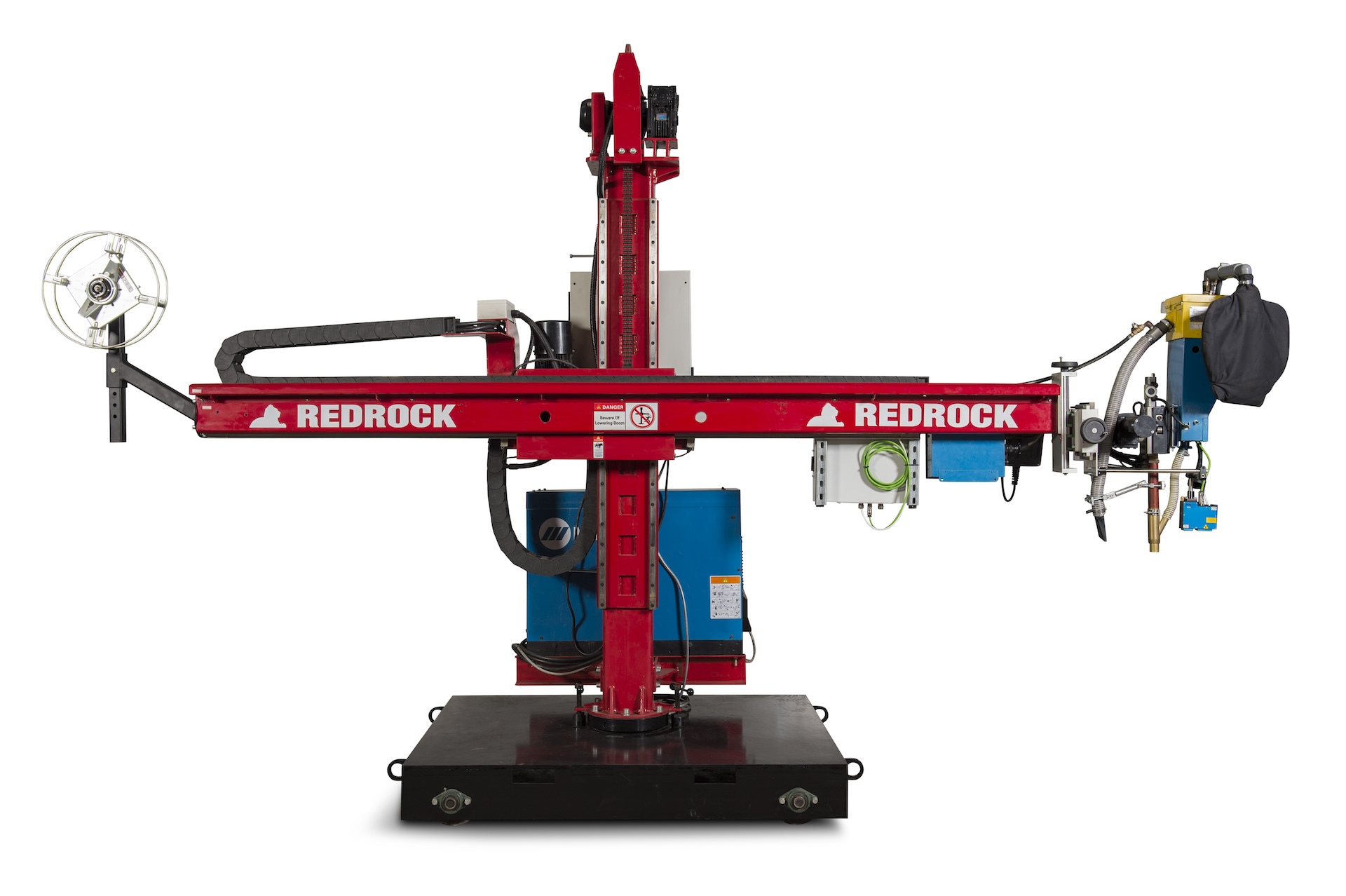

Redrock has a huge inventory of welding manipulators suited to any welding application, providing a safe and efficient welding procedure suited to multiple industries.

Speak to our team to discover a bespoke solution for your welding automation requirements.

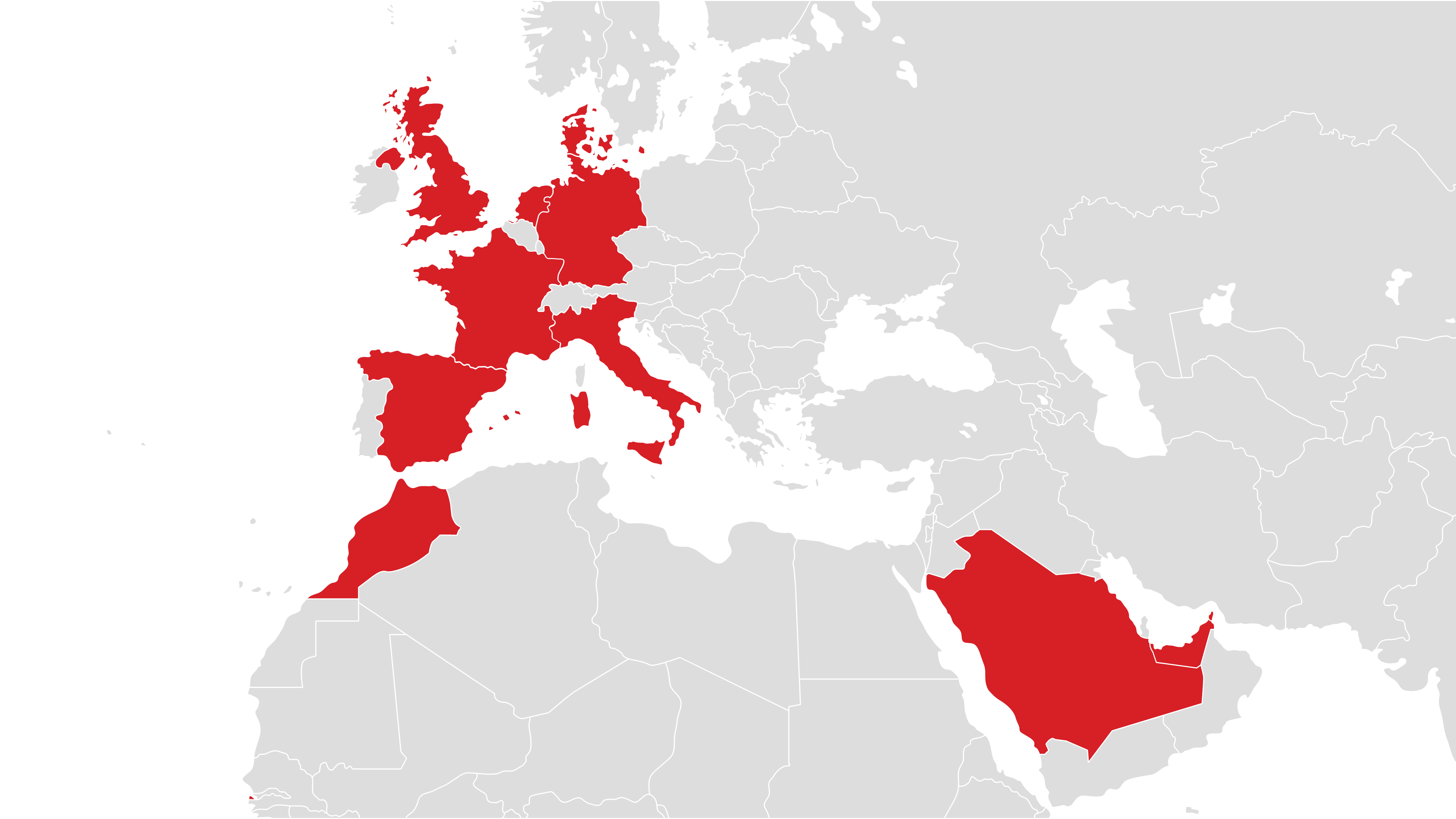

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.