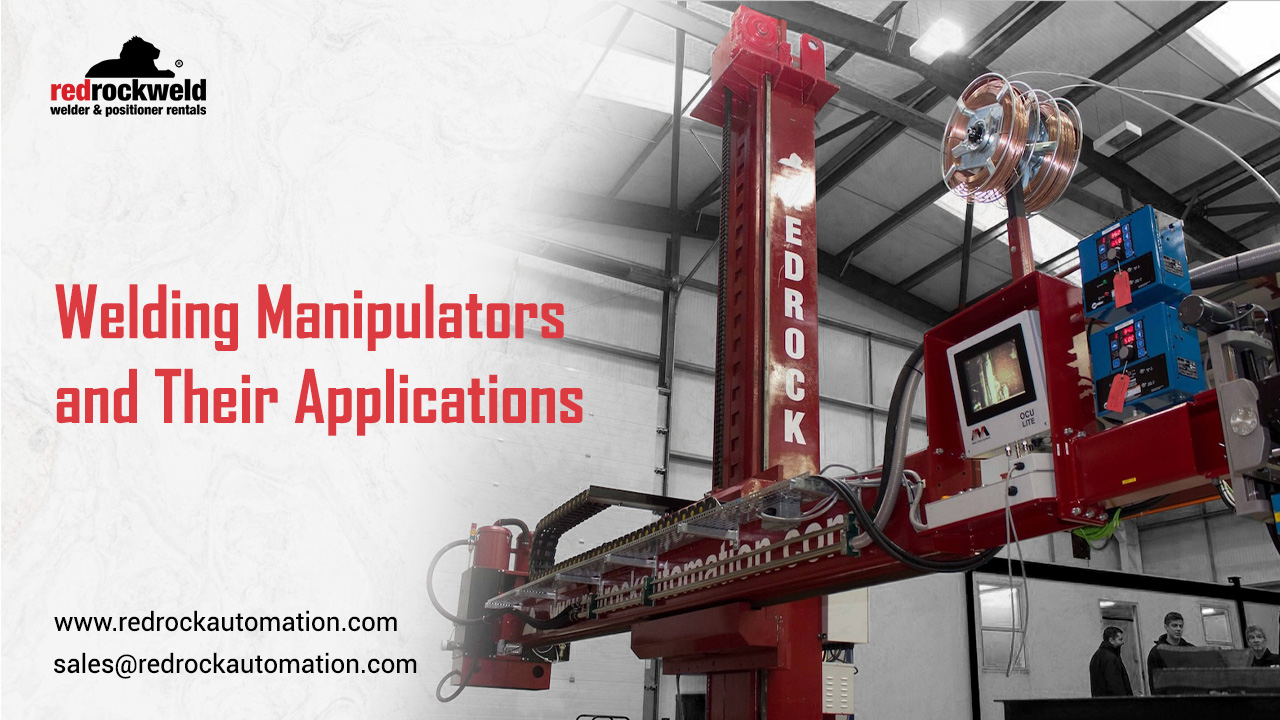

Welding Manipulators and Their Applications

Large-scale fabrication of metals is simply impossible without accurate welding. It is the backbone of modern infrastructure. The welding equipment and torches’ manual handling are often strenuous and time consuming. And that’s where welding manipulators come into play. They streamline the welding task by consistently supporting the welding torches throughout the process. In this blog, we will delve into welding manipulators and their applications.

What are Welding Manipulators?

Welding manipulators are devices designed to secure the welding torch, ensuring that it’s positioned properly to achieve accurate weld. It automates the handling of the welding torches and holds it in the optimal position to achieve the right weld.

It consists of a base, a column, and a boom- the conjoined arm and the weld head at the end of the arm. The manipulator can be adjusted to position the welding torch according to the specificity of the task at hand.

This relieves the operators from physical strain, repetitive motion, and precision challenges that accompany manual handling

Applications of Welding Manipulators

Where consistent and efficient welding becomes essential, welding manipulators help to achieve precise and quality welds. Here are some of the typical applications of welding manipulators.

● Pipeline Manufacturing:

Welding manipulators will help to achieve long and uniform welds for pipe joints by accurately positioning the welding torch.

● Shipbuilding:

It is particularly crucial in large-scale manufacturing such as shipbuilding. It accurately positions the welding head at the right spot and helps to weld huge and complex ship components

● Aerospace:

The manufacturing of large components of aircraft frames, such as wings, fuselage, and landing gears, can be effectively carried out using welding manipulators.

It renders the welding head’s perfect positioning and ensures that consistent and quality weld is obtained. This way, the structural integrity of the parts are guaranteed.

● Automotive industry:

The tasks of the automotive industry demand precise welding. It aids in the meticulous welding of the various components of vehicles, such as the chassis or the frame.

● Tank and Vessel Fabrication:

Welding manipulators will help the torch to reach and weld the particular parts of vessels or tanks which are difficult or to reach manually. In addition to that it helps to maintain the consistent speed without compromising the quality.

● Production of Heavy Machinery:

When it comes to the welding heavy machinery like tractors, cranes and mining equipment, welding manipulators ensure that the welding torches can traverse through the components with ease

Conclusion

From pipe manufacturing to heavy machinery production, welding manipulators find their application in diverse industries. What makes it a crucial addition is undoubtedly its capacity to speed up the welding process by clamping the welding torch and aligning it in the exact position to achieve maximum output. At RedRock Automation we provide a top-tier range of welding equipment. Whether for purchase or rental, we ensure you get the best welding manipulator that suits your fabrication needs.