- For Hire

- For Sale

- Our Fleet

- Used Equipment

Experience smooth rotation and precise welding operations with conventional welding rotator hire from Redrock.

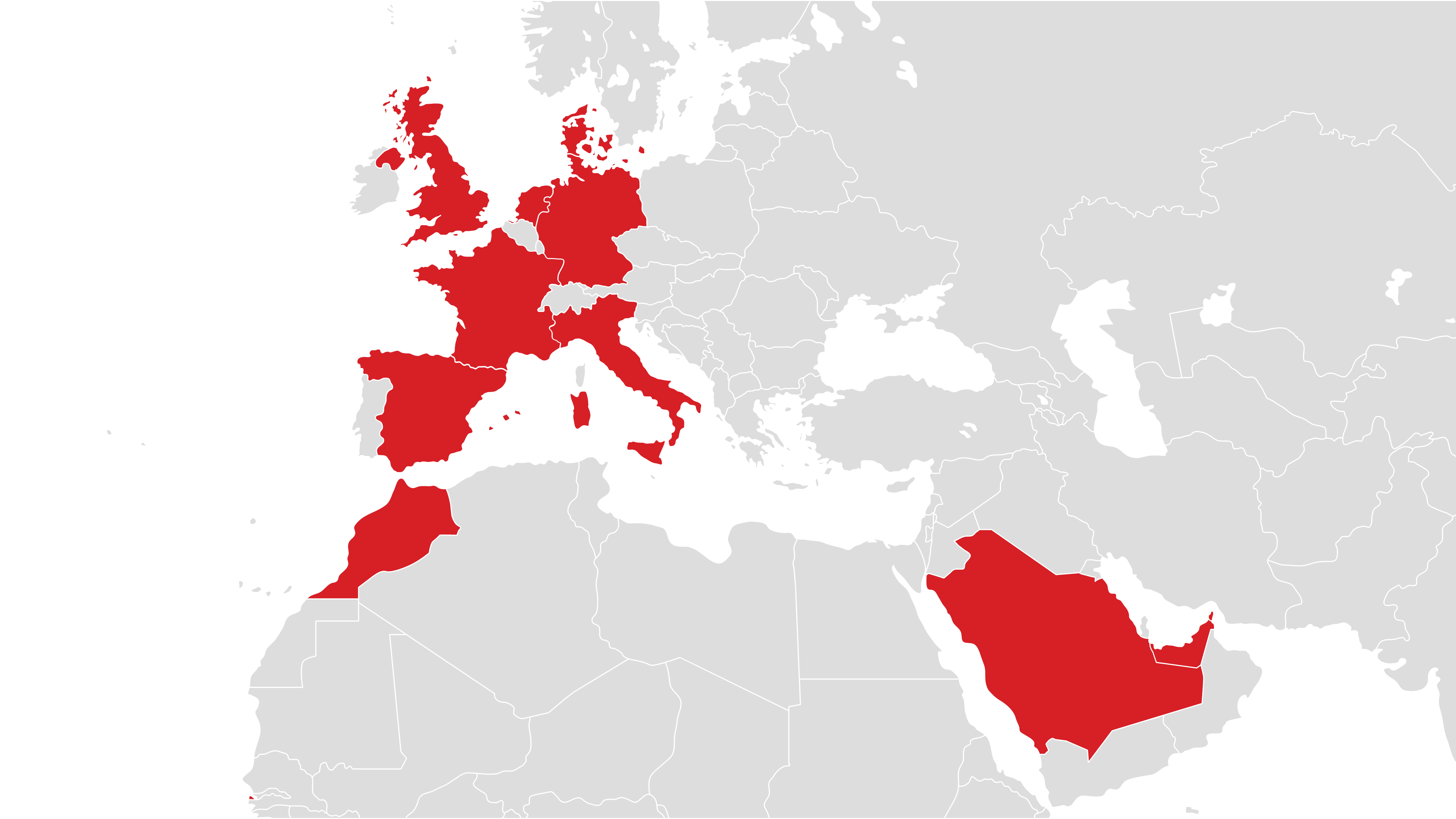

Our range of conventional rotators is available for shipping worldwide from our global facilities, with in-house expertise to provide you with a bespoke solution for your needs and welding rotators built to withstand different diameters and load capacities.

Our conventional rotators provide the best-in-class welding equipment to deliver efficient and effective welding operations.

Rotate cylindrical vessels quickly and efficiently with a heavy-duty conventional welding rotator chosen for your exact requirements and flexible rental options to accommodate your exact needs.

All our rotators are 100% steel (base frame and drums) with polyurethane tyres providing cushioning on load and minimising shock.

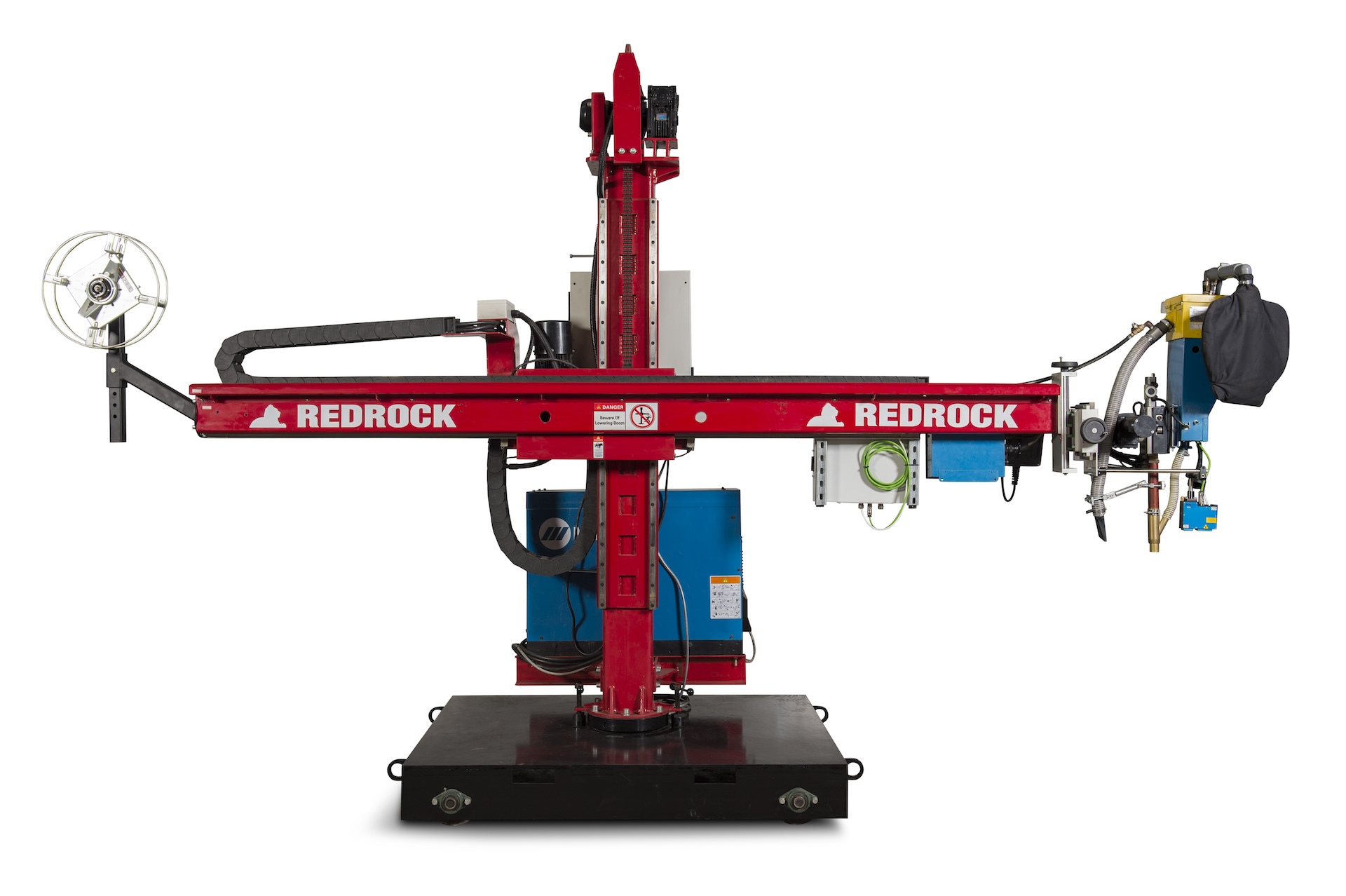

Conventional Welding Rotators

Our range of conventional welding rotators uses drive and idler units to optimise the movement of the rotating workpiece with a base frame and rotator wheels primely positioned to support the process effectively and efficiently.

A conventional welding rotator can improve accuracy and precision in the rotation of cylindrical vessels, reducing the time and manual effort required for your welding operations. With precise rotation goals met, your welders can focus fully on the welding operations.

Conventional rotators offer enhanced safety for your team whilst ensuring the specific needs of your welding operations are met. Features including an emergency stop button, powered drive units and a remote control pendant mean your team is always in full control of the rotation speed and forward & reverse motion.

A conventional welding rotator provides precise rotation control, ensuring accurate welding operations for every use case. Our fleet of conventional rotators is equipped to accommodate different vessel diameters, from 90 mm to 14 metres providing a versatile and adaptable solution for any welding process.

Redrock supplies top-of-the-line welding equipment worldwide – with teams of experts located throughout the world, we’re on hand to help businesses secure the right solution for their next job.

We offer cost-effective solutions and flexible rental terms, whether you require a long or short-term lease. No matter the scale or complexity of your next job, we can provide support and expertise to find the optimum conventional welding rotator for your needs.

All of our quality rental equipment is fully serviced and maintained. When you hire from Redrock, there’s no need to carry spare parts, be burned with repair costs or worry about maintenance. You can rest assured that everything is handled by our trained service engineers.

Redrock is uniquely positioned to understand the pressures of the welding industry. We provide the best-quality welding positioners to help our clients increase their throughput to gain a competitive edge.

Our welding turntables are built to a heavy-duty precision design and are suitable for various applications, from fit-up and assembly requirements to integrated cladding and overlay applications.

Redrock has a huge inventory of welding manipulators suited to any welding application, providing a safe and efficient welding procedure suited to multiple industries.

Frequently Asked Questions

Conventional rotators are ideal for performing both industrial welding and fitting out operations involving smaller or larger diameter vessels with longer length sections which sometimes require enhanced turning capacity.

Redrock’s conventional rotators are suitable for industrial applications requiring a higher load capacity of up to 2,000 tonnes. Our conventional rotators are suited to a wide range of fabrication shop setups. The wheel centre diameters can be adjusted manually with speed. All our welding rotators use replaceable polyurethane tyres, mounted to cast steel drums to give the units durability and superior traction.

As standard with all our equipment, a low-voltage remote-control pendant is included to give your operators full control over forward/reverse/stop/emergency stop and a potentiometer for variable rotation speed.

Our flexible rental terms mean you’ll be equipped with an industry-leading conventional welding rotator when you need it, and you can easily return it to us when your project is complete.

With the use of welding rotators, your processes will benefit from:

Our conventional rotators have load capacities of up to 2,000t, offering a heavy-duty solution for a variety of welding processes. We offer numerous features and customisation options to guarantee the best possible result and weld quality, including enhanced safety features and a remote-control pendant supplied as standard.

Each of our conventional rotators is fully serviced, warrantied for three years and fully tested before dispatch, so you can ensure your welding rotators are suitable for extensive use.

The Redrock team is committed to providing you with the best conventional rotator for your needs that will increase productivity – our highly experienced professionals can advise you on the right rotators that will suit your requirements.

Speak to our team to discover a bespoke solution for your welding automation requirements.

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.