- For Hire

- For Sale

- Our Fleet

- Used Equipment

Redrock’s range of welding manipulators for hire and rental provides a flexible solution for safe and efficient welding processes. Welding manipulators are designed to move the weld head over the workpiece, in contrast to positioners or rotators, which move the workpiece rather than the welding head.

Our huge inventory of welding manipulators, including column and boom manipulators (C&B), is suited to any welding application, providing the quickest means of rotating and tilting through 360 degrees and equipped to cope with the most demanding of environments – no matter your requirements.

Welding Manipulators

Redrock’s hire service offers short-term lease arrangements for one-off projects and cost-effective rentals for longer-term solutions.

We stock a wide variety of welding manipulators with platform sizes ranging from 2m x 2m up to 10m x 10m, with motorised cars available for faster production rates. Column and boom manipulators are the perfect solution for welding pressure vessels, tubular sectioning and pipe and tank applications.

Redrock is a leading manufacturer of all types of welding automation equipment, featuring all-steel construction to cope with the most demanding of work environments.

Our team consists of highly skilled engineers and technicians who are driven to provide our customers with results-focused advice. We have a proven track record for providing quality welding automation solutions to a variety of sectors.

Whether you require a short-term lease for one-off projects or a longer-term rental solution, renting welding equipment allows you power your workforce with the tools they need for the task at hand without the added expenses of outright ownership.

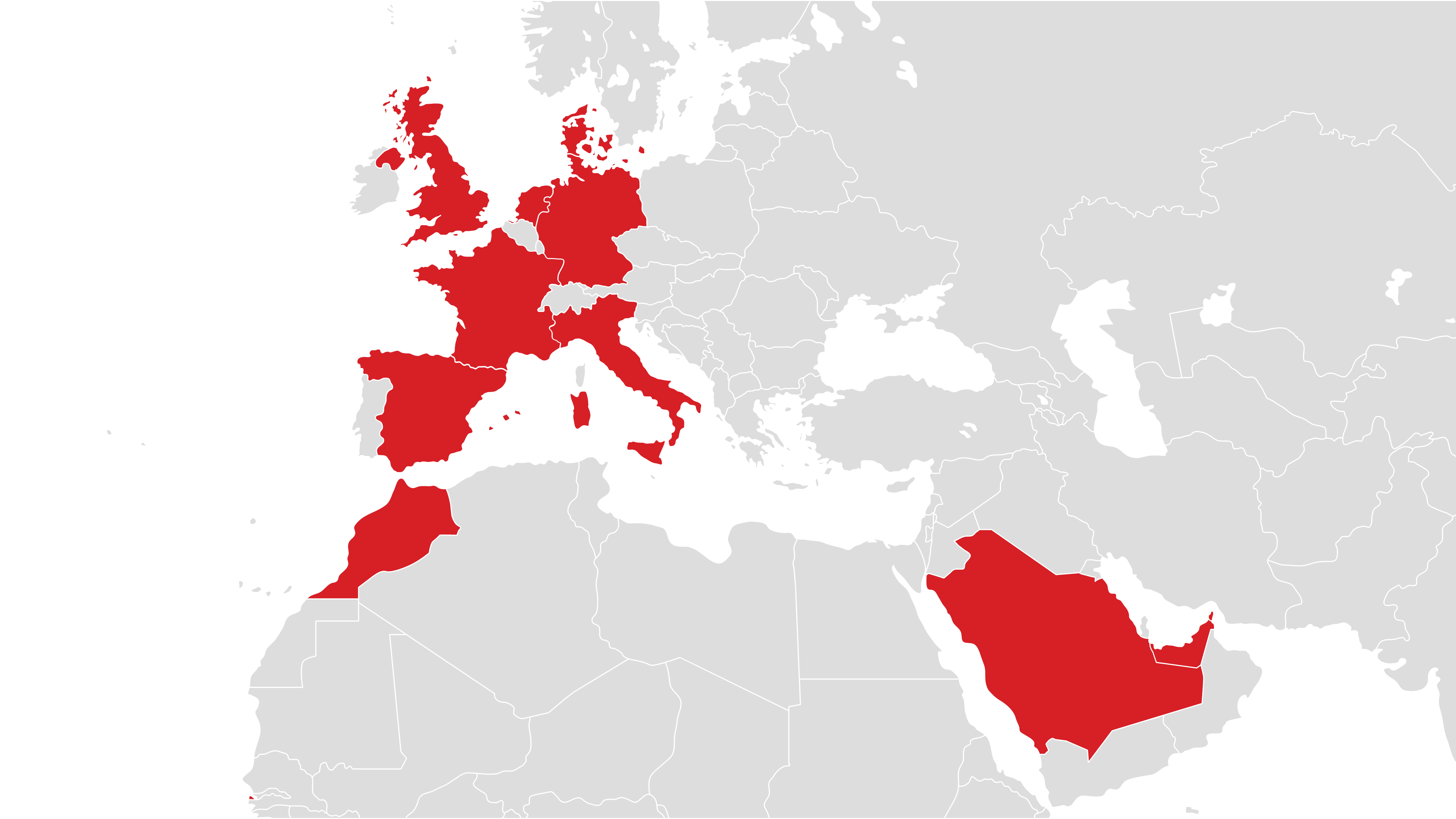

With rental depots located throughout the world, we’re in a perfect position to supply all types of specialist welding equipment internationally. If you experience any problems with your equipment, our service engineers will be available to get things back up and running smoothly.

With our equipment hire service, you only pay for equipment when you use it. Suppose you’re going to use a welding manipulator less than 60% of the time. In that case, chances are you’ll lower your operational costs by hiring a manipulator on an as-needed basis, rather than buying one.

One other major advantage of hiring with us is you don’t need to carry pricey inventory on a whim that you may need on future projects. Market conditions fluctuate and businesses go through ups and downs – we’re here to supply your equipment during your ups and when projects slow down, we’ll take them off your hands.

Whatever your welding operation process, Redrock can help your business upgrade to the latest technological solutions to improve production, while simultaneously lowering your wastage cost and costly rework jobs.

Speedy deliveries can be arranged – ideal for meeting tight project deadlines and work schedules.

Forget the expense of testing, maintenance and servicing. All our welding equipment for hire is fully serviced, maintained and ready to be put into operation. Our entire fleet boasts maximum safety features, ensuring your operators can work fast without compromising safety.

Frequently Asked Questions

Hiring a welding manipulator to support your next project brings with it a range of benefits:

A welding manipulator is a piece of equipment that assists the welding process by helping welders reach particular areas that require welding operations.

When integrated with manufacturing and welding processes, a welding manipulator can offer higher-quality outputs and reduce worker fatigue to ensure a smooth welding operation from start to finish.

Redrock’s range of conventional and self-aligning welding rotators provides an economical and practical answer to cylindrical vessel rotating and handling problems.

Redrock is uniquely positioned to understand the pressures of the welding industry. We provide the best-quality welding positioners to help our clients increase their throughput to gain a competitive edge.

Our welding turntables are built to a heavy-duty precision design and are suitable for various applications, from fit-up and assembly requirements to integrated cladding and overlay applications.

Speak to our team to discover a bespoke solution for your welding automation requirements.

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.