- For Hire

- For Sale

- Our Fleet

- Used Equipment

Self-aligning welding rotators provide an efficient way to enhance your welding processes with seamless, high-precision equipment. If your industrial applications requiring load-bearing equipment are in need of an upgrade, investing in a self-aligning welding rotator can elevate your setup and promote longevity for business operations.

Built for small and heavy-duty applications, our range of self-aligning welding rotators improves efficiency, maximises precision and upgrades operator safety for the welding of storage tanks, pressure vessels and countless welding operations.

Upgrade your welding processes with a long-term investment in precision and quality with a self-aligning welding rotator.

Each of our self-aligning rotators are 100% steel (base frame and drums), with polyurethane tyres that cushion the load, minimise shock and protecting the self-aligning rotators from potential damage due to negligent loading. Our available models support capacities from 5 tonnes to 1,000 tonnes.

Self-Aligning Welding Rotators

Investing in a self-aligning welding rotator offers a long-term, high-performance solution for your welding operations. Engineered to automatically adjust to the diameter of cylindrical vessels, these self-aligning rotators eliminate the need for manual wheel positioning with automated adjustments, ensuring seamless rotation, superior weld quality and increased efficiency in large-scale welding applications.

Self-aligning welding rotators can streamline your operations by producing a controlled automated welding process, reducing setup time and minimising manual intervention with automated adjustments. With an idler and drive unit working in perfect sync, self-aligning rotator operators can focus fully on the welding process rather than adjusting equipment, leading to faster turnaround times and improved workflow.

Self-aligning rotators reduce the need for manual adjustments and heavy lifting, contributing to a safer working environment. With control and automated handling provided by the self-aligning rotator, your workplace will be equipped to handle everything from smaller-scale jobs to large-scale pipe diameter and pressure vessel welding applications.

With a self-aligning welding rotator, you’re guaranteed precise rotation control and automated handling when welding all vessel sizes, from thin-walled vessels to larger pipe-turning jobs. By maintaining alignment throughout the welding process, self-aligning rotators help eliminate defects, enhance quality and support high-precision applications across industries.

Redrock is uniquely positioned to understand the pressures of the welding industry. We provide the best-quality welding positioners to help our clients increase their throughput to gain a competitive edge.

Our welding turntables are built to a heavy-duty precision design and are suitable for various applications, from fit-up and assembly requirements to integrated cladding and overlay applications.

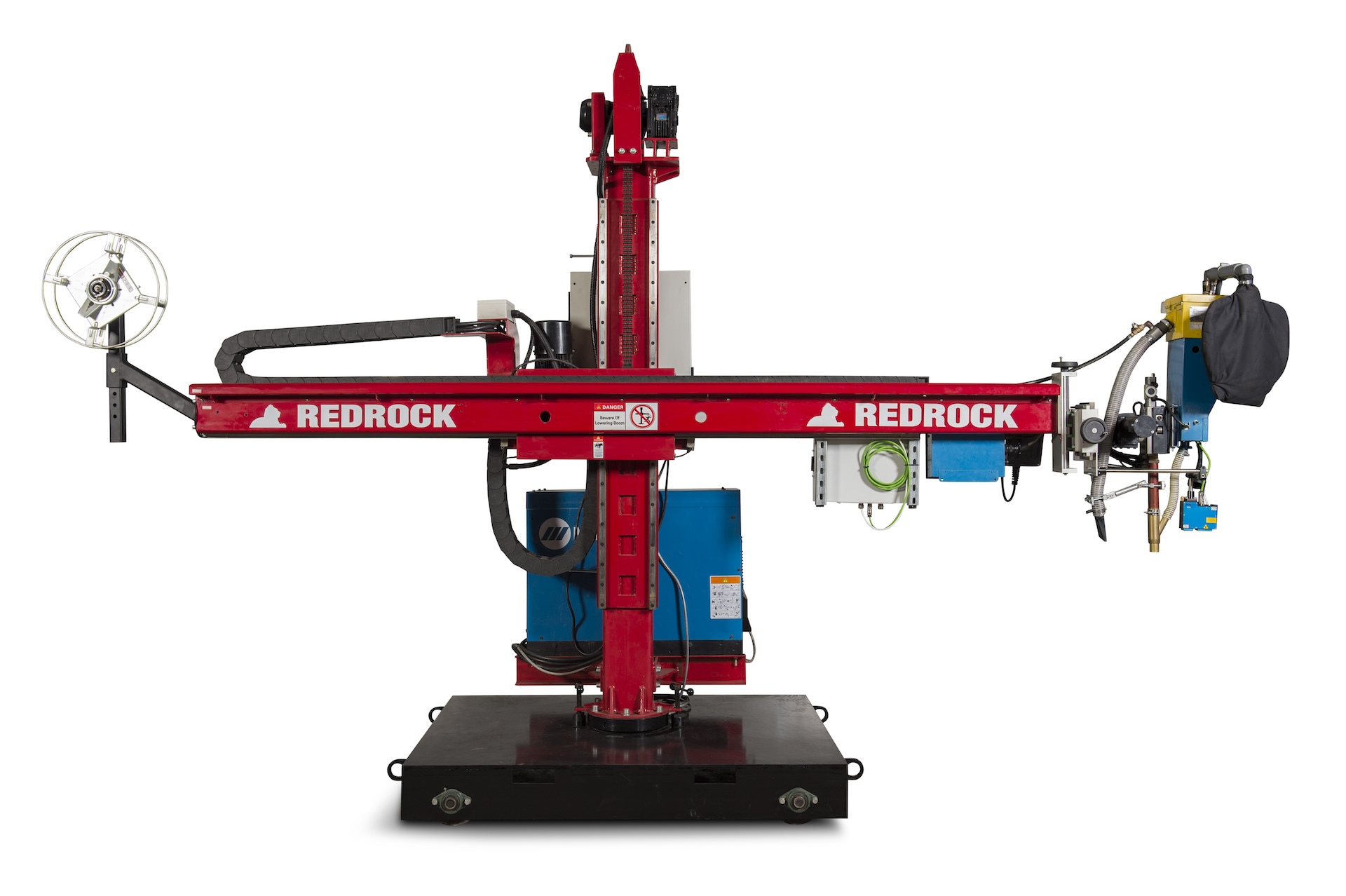

Redrock has a huge inventory of welding manipulators suited to any welding application, providing a safe and efficient welding procedure suited to multiple industries.

Frequently Asked Questions

Self-aligning welding rotators are suited to multiple applications including boilers, tanks, heat exchangers, barrels and pressure vessels.

Redrock’s self-aligning rotators are robustly built with high-load capacities of up to 200 tonnes. Our self-aligning drive units are fitted with dual-sided motorised wheels and idling units allowing free-wheeling, making it easier to load vessels onto the rotator without damaging the unit.

Our self-aligning welding rotators utilise roller modules that adjust to accommodate the diameter automatically. A range of specifications can be accommodated, including various diameters and rotation speeds.

With the use of self-aligning welding rotators, your processes will benefit from:

Self-aligning rotators can provide faster load times with mechanical drive, where the wheel brackets and the wheels will automatically align to any pipe diameter. Four rollers instead of two give you the support rigidity on larger-diameter applications.

Designed to automatically adjust to the diameter of cylindrical vessels, our self-aligning rotators eliminate the need for manual wheel positioning, ensuring seamless rotation, superior weld quality and increased efficiency in large-scale welding applications and pipe-turning jobs.

Speak to our team to discover a bespoke solution for your welding automation requirements.

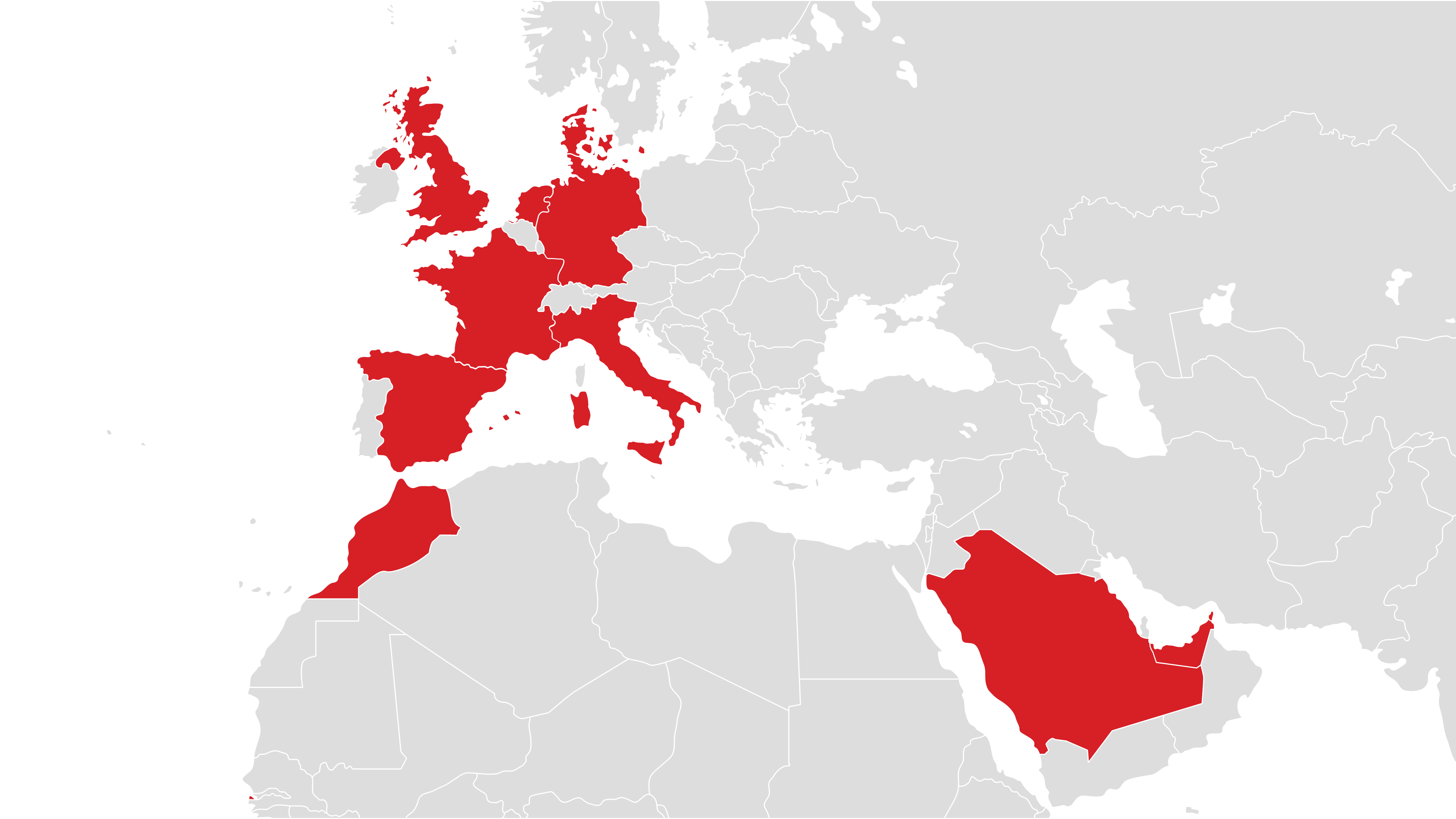

We provide a range of welding equipment solutions from our multiple international facilities with worldwide shipping.